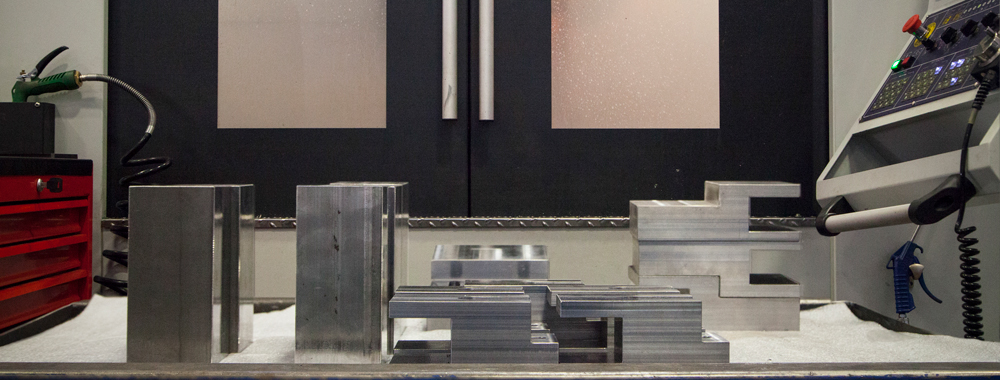

Targeted design, precision, speed: these are the quality parameters that distinguish the scrap removal department.

Numeric control machines operate according to the instructions set in the preliminary machine design and programming phase, making computer support a key step in achieving perfect results.

Six specialised operators work on these processes, providing their high value support to automated and engineered parts. Indeed, our resources’ sensitivity, experience and extreme care complement the high quality mechanical work.

The tools found in this sector of the workshop include a lathe, a mill and two work centres, allowing different operations to be performed on the same machine. Each tool works by exploiting scrap removal, a technique that eliminates the risk of material deformation since it starts with solid material that is accurately shaped. Basically, the material takes on the desired shape as the tools remove excess parts.

The simultaneous use of all these machines in the company results in exceptional processing and delivery speed, two key elements to being competitive and constantly maintaining close customer relations.

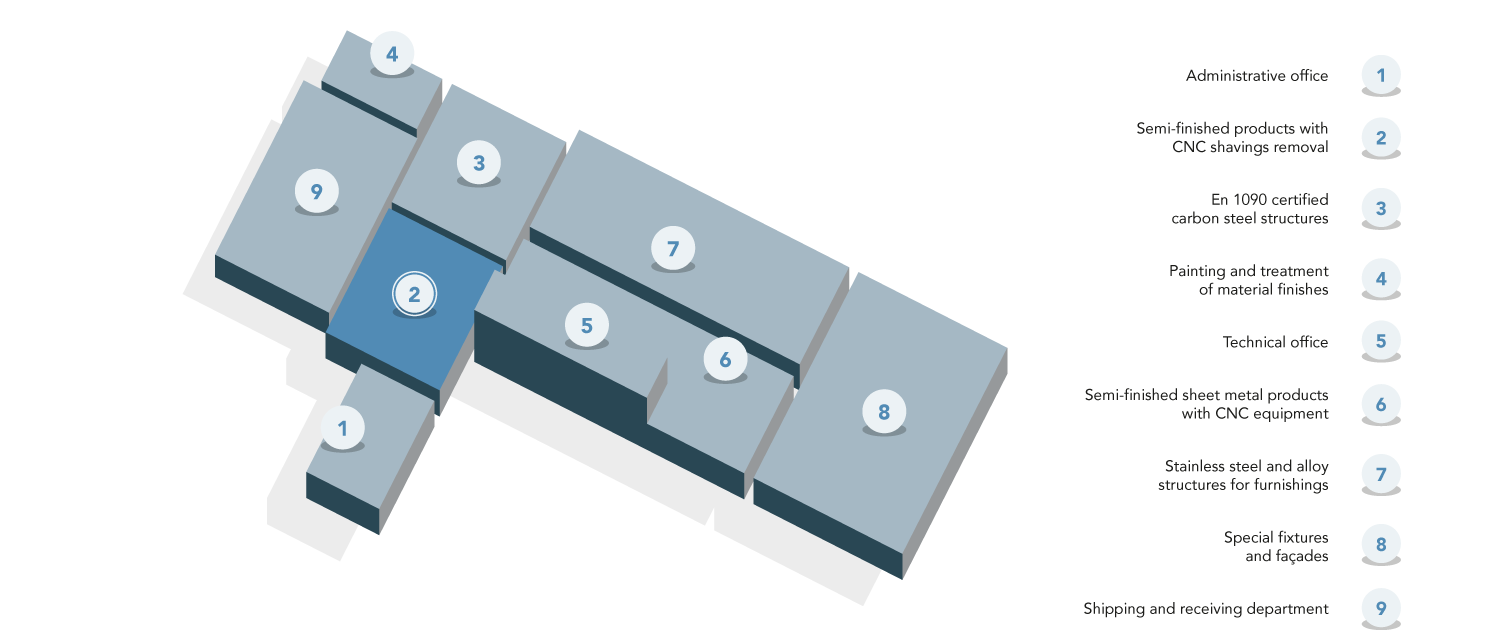

From concept to assembly

We are not merely craftsmen who limit our tasks to performing a job: we accompany our customers, or the architects they have appointed, from concept to the choice of the best materials and products. We create engineered technical drawings with the necessary construction solutions, we produce and install, providing turnkey solutions.